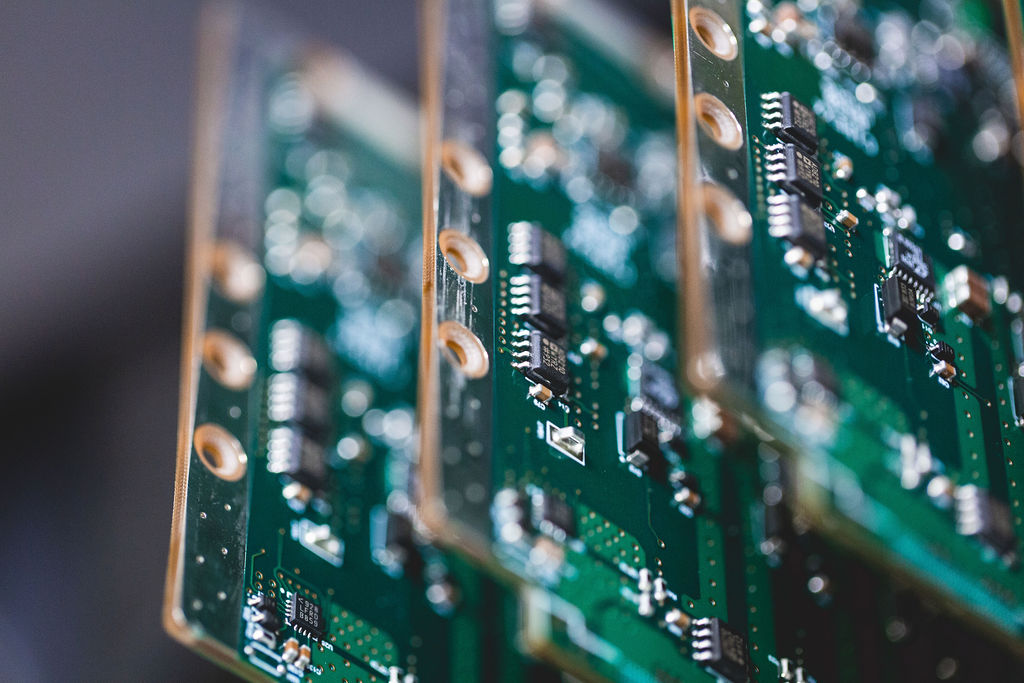

Whether you are a large corporation attempting to launch a new product or a tiny business owner fantasising about promoting your next amazing device, you will come across the cryptic term “PCB” at some point. It’s known as a “printed circuit board,” and we see it all the time. What are the similarities between an MP3 player, a TV, a DVD player, and a NASA spacecraft? Each one contains a circuit board that houses and connects all of the necessary parts. Most modern boards contain numerous layers in order to fit more parts on a smaller surface area.

How much does it cost to manufacture a multi-layer PCB?

PCB manufacturing with more than one layer is no longer prohibitively expensive. Prices have decreased as more businesses offer printing services. This is due to the advancement of technology.

Consider a two-inch-by-four-inch circuit board with four layers. You don’t need any more supplies if it’s for home electronics. Because the engineers need to work on your Gerber files, update them, and set up the printing equipment, there is usually a one-time setup fee. Although it requires effort, the setup charge will virtually never exceed $200. However, it will be better suited for detailed designs.

Prices per unit are determined by the materials used, the number of holes and channels that must be drilled, and other considerations. You can receive better discounts when you order more, much like you can with publishing books and other printing services. A 100-board test batch can cost more than $2 per board. When you buy over 10,000 pieces, each one costs around $1.

High-temperature materials are typically twice as expensive per unit, but you must accept this when you need them. Obtaining components at a lower cost could make or break the success of your product.

The best option isn’t necessarily the most affordable.

As we discuss further, make sure you select a multilayer China PCB fabrication business with a proven track record. Many new business owners and individuals developing new products attempt to save money by having their boards manufactured in Asian countries, but they fail to recognise that local enterprises provide far superior quality.The price difference is not significant because the process of producing a multilayer China PCB is almost entirely automated and requires only a minor amount of human labour.

The United Kingdom, Germany, and other European countries are home to some of the world’s top electronics manufacturers. The Yellow Pages may be the best place to look for a dependable person to work with. Look for local companies. You’ll have more say over how things turn out, and shipping will be much faster. If you found the company online, go to their website to find out how to contact them. Always compare the address to the domain name. They should be compatible or live in the same nation.

With so many new websites and electronics businesses opening each month, it’s easy to be duped or receive poor service. Hence, conduct extensive background research before you decide on the multilayer PCB manufacturing staff you want to work with.