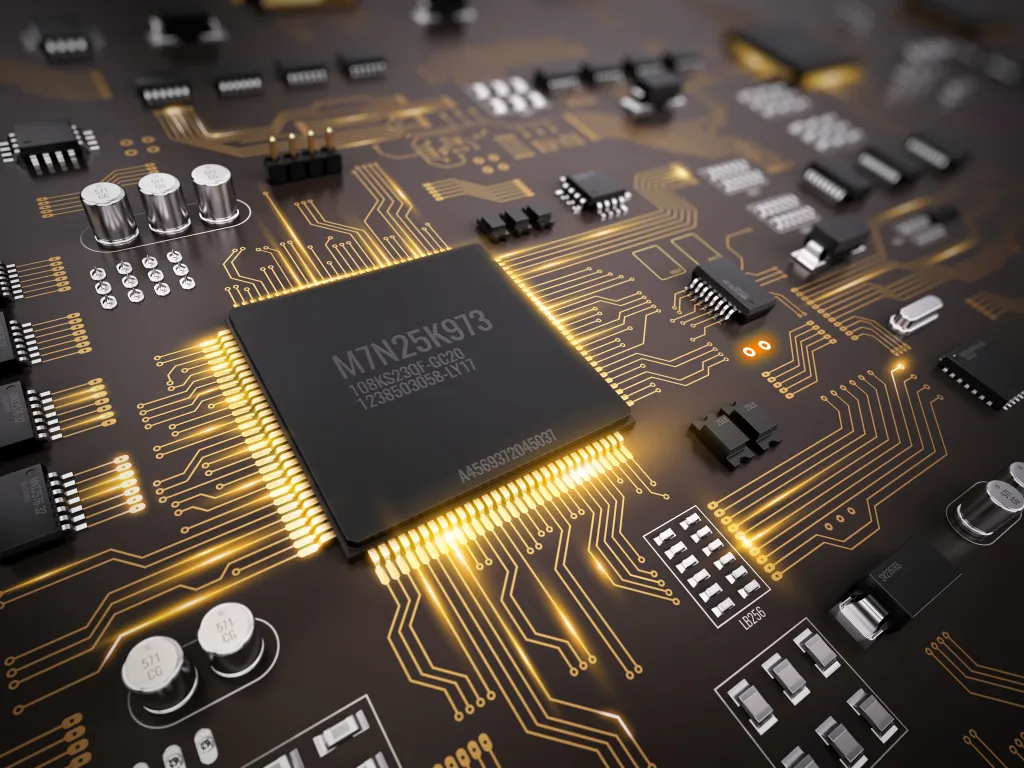

When we think of modern technology, our minds often turn to smartphones, laptops, and other devices that we use every day. But have you ever stopped to consider what’s inside these devices?

One essential component that makes all modern electronics possible is the printed circuit board, or PCB. PCBs are everywhere.

They’re in your phone, your computer, your car, and even in medical equipment like pacemakers and MRI machines. Without them, our world would look very different.

Starting with the Design Process

Creating a PCB design involves planning and following a series of steps to ensure that the circuit board operates as efficiently as possible. The first step in designing a PCB is to create a schematic diagram that shows how the components are connected. Once this is complete, designers can begin transferring the schematic into a physical board layout, where they will place components and trace connections between them.

Software and Tools for PCB Design

Designing a printed circuit board requires specialized software that helps engineers plan, design, and test their circuit boards before sending them off for production. Some of the popular tools used in PCB design include Altium Designer, Eagle PCB Design Software, KiCad EDA, and CircuitMaker.

These programs allow users to create complex designs with ease and avoid common mistakes related to component placement or tracing errors. With all of their advanced features, these programs make it possible to develop precise schematics for even the most demanding projects.

Mistakes to Avoid in PCB Design

Designers, like https://www.avanticircuits.com, have many variables they need to balance when creating printed circuit boards. While technology has made it easier than ever before to design complex circuits accurately, there are still some common mistakes that can occur during the process.

One mistake frequently made is forgetting about thermal management which can cause overheating issues or cause components to fail prematurely. Another mistake is failing to double-check traces after editing which can lead electrical shorts resulting from incomplete connections or even open circuits if connections are cut off altogether.

Designing an effective printed circuit board requires careful planning through every stage of development- from schematics creation through final testing. By using specialized software tools and avoiding common mistakes like thermal management concerns or poor trace checking habits- designers can help improve overall quality while reducing costs associated with manufacturing errors down the road.